Instrument Support Level 3

Michell Instrument, S8000

Not Applicable

Calendar

High Performance Precision Dew Point Meter

The S8000 Remote has all the great features of the other S8000 Series chilled mirror hygrometers, but with a convenient and compact remote sensor design.

The field-proven sensor boasts upgraded temperature control for extremely accurate dew-point measurement. Coupled with the standard ±0.1°C accuracy ambient temperature sensor, it provides fundamentally derived, high precision relative humidity readings necessary for validating the results of environmental tests.

Product Features

- Fundamental, accurate and drift-free measurement

- Remote sensor

- Open design allows the remote sensor to be mounted into a sample flow or simply placed in an environment to be monitored

- -40 to +120°C dew-point range with ±0.1°C accuracy

- ‘FAST’ guarantees frost formation below 0°C

- The sensor operates in pressures up to 20 barg

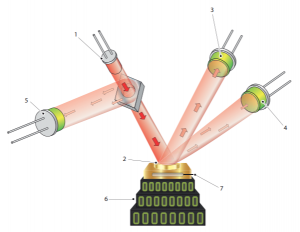

The chilled mirror sensor consists of a temperature-controlled mirror and an advanced

optical detection system.

Michell Instruments S8000 sensors utilize our RRS Optical System to guarantee 0.01°C (0.018°F) sensitivity and the fastest dynamic response to dew points as low as –90°C (–130°F). The system employs active monitoring and adjustment to automatically rebalance the optics to accommodate any changes in RRS the signal level not associated with condensed moisture.

A beam of light from an LED (1) is focused on the mirror surface (2) with a fixed intensity. As the mirror is cooled, less light is reflected due to the scattering effect of the condensate formed on the mirror surface. The levels of reflected and scattered light are measured by two photo-detectors (3 & 4) and compared against a third reference detector (5) measuring the intensity of light from the LED.

The signals from this optics system are used to precisely control the drive to a solid-state thermoelectric cooler (TEC) (6), which heats or cools the mirror surface. The mirror surface is then controlled in an equilibrium state whereby evaporation and condensation are occurring at the same rate. In this condition, the temperature of the mirror, measured by a platinum resistance thermometer (7), is equal to the dew-point temperature of the gas.

Dynamic Contamination Control (DCC) ensures that measurement accuracy and stability are maintained even when contamination is present on the surface of the mirror. During the DCC process, the mirror is heated to approximately 20°C (36°F) above the sensor temperature to remove the condensation which has formed during measurement.

The surface finish of this mirror, with the contamination which remains, is used by the optics as a reference point for further measurements. This removes the effect of contamination on accuracy

In carefully controlled laboratory conditions, super-cooled water can exist in temperatures as low as –48°C (–54°F). However, when using a chilled mirror instrument it only occurs on the mirror at temperatures down to around –30°C (–22°F). The difference in vapor pressure between condensed water and ice formed on a chilled mirror can introduce dew-point errors of up to 10% of reading. It is also possible for intermediate states to exist, where the formation is a mixture of ice and super-cooled water, making calculated conversions from one state to the other invalid.

All Michell Chilled Mirror Products feature FAST, the frost assurance technology which guarantees all dew-point measurements below 0°C (+32°F) are made over ice. The FAST system works by detecting whether the mirror is at a temperature where supercooled water could form, and if so; rapidly cooling the mirror until a film of ice of predetermined thickness forms. Once ice has formed, control returns to the instrument and measurement can begin.

The system is calibrated bt Michell Instruments every 2 years.

The chilled mirror is free from temperature dependence and remains accurate and drift-free across the entire measurement range. All of our chilled mirror instruments are delivered with calibrations performed against test equipment traceable to NPL and NIST national standards through Michell’s ISO/IEC 17025 UKAS accreditation.

Data from instruments that are part of a laboratory do not archive their data to CEDA and so do not have to conform to any AMOF standard.

Data can be provided for the period of time that the user has accessed the facility.