Instrument Support Level 2

Teledyne T200UP

ncas-teledyne-t200up-nox-1

nox-noxy-concentration

£40,000

17.8 cm x 43.2 cm x 59.7 cm, 28kg

44 cm x 23 cm x 79 cm, 32kg

£20

Calendar

TELEDYNE T200UP NOx Analyser

The Model T200UP provides trace level measurements of NO and NO2 using our Model T200U NOx analyzer combined with a patented high-efficiency photolytic converter. Even low-temperature molybdenum converters transform other nitrogen-containing compounds such as HNO3, PAN, etc. to a considerable extent. Simultaneous measurements of NO2 performed with molybdenum and photolytic converters have shown significantly different results in the presence of such compounds.

In the photolytic process, the sample gas passes through a cell where it is exposed to light at a specific wavelength from an LED array. This causes the NO2 to be selectively converted to NO with negligible interference from other gases. Combined with the proven Model T200U, it provides ultra-sensitive performance, with a lower detectable limit of 0.05 ppb or better, and is ideally suited for NCore research sites and the low-level direct NO2 measurements required for roadside monitoring. Advances in the photolytic converter technology now yield NO2 conversion efficiency that is similar to molybdenum under typical ambient NO2 concentrations but without the same interferences.

The Model T200UP operates on the principle that nitric oxide (NO) and ozone (O3) react to produce a characteristic luminescence with an intensity linearly proportional to the NO concentration. Infrared light emission results when electronically excited NO2 molecules decay to lower energy states. Specifically:

NO + O3 → NO2 + O2 + hν

The ambient air sample is drawn into the instrument through the sample bulkhead, to the prereactor solenoid valve.

The prereactor solenoid valve directs the sample either to the reaction chamber, where it mixes with ozone to give an NO reading or to the prereactor, where it reacts with ozone prior to the reaction chamber giving a dynamic zero reading for the analyzer. The prereactor is sized so that greater the 99% of a 200 ppb NO sample will react prior to entering the reaction chamber, yet is small enough to allow other potential interferents to pass through to the reaction chamber.

Dry air enters through the dry air bulkhead, passes through a flow switch, and then through a silent discharge ozonator. The ozonator generates the ozone needed for the chemiluminescent reaction. At the reaction chamber, the ozone reacts with the NO in the sample to produce excited NO2 molecules. A photomultiplier tube (PMT) housed in a thermoelectric cooler detects the luminescence generated during this reaction.

The NO concentrations calculated are stored in memory. The instrument outputs NO concentrations to the front panel display, the analog outputs, and also makes the data available over the serial or Ethernet connection.

The calibration technique is based on the rapid gas-phase reaction between NO and O3 which produces stoichiometric quantities of NO2 in accordance with the reaction:

NO + O3 → NO2 + O2

The quantitative nature of this reaction is such that when the NO concentration is known, the concentration of NO2 can be determined.

Ozone is added to excess NO in a dynamic calibration system, and the NO channel of the chemiluminescence NO-NO2-NOx analyzer is used as an indicator of changes in NO concentration.

When O3 is added, the decrease in NO concentration observed on the calibrated NO channel is equivalent to the concentration of NO2 produced. Adding variable amounts of O3 from a stable O3 generator can change the amount of NO2 generated.

The instrument is calibrated before deployment.

Consumables

The user will need to supply:

- 1 x 450 ppb nitric oxide certified standard, cylinder size AV

- Chemsorb1000

Costs

- Instrument Insurance

- This system must be insured by the user for £30K and covers loss, theft or damage to the instrument: damage is that over and above general wear and tear. The system has been designed to be rugged and autonomous. Even so, the end-user must respect the fact that the system is a precision optical instrument that must be treated with great care.

- The user is responsible for the instrument from the time it leaves the AMOF to the time it is returned and signed off as in an acceptable operating condition by the IS: this will be done as soon as is possible on its return.

- Public Liability Insurance

- The AMOF is not liable for any damage or injury arising from the deployment or operation of this instrument when unattended by the IS.

- Shipping Expenses

- The user is liable for all costs arising from the shipping of the instrument both to and from a deployment.

- IS T&S

- The user is responsible for coving the travel and subsistence expenses of the IS while attending the instrument.

Shipping

The system when packed ready for shipping consists of a single box:

- Shipping dimensions:

- 44 cm (W) X 23 cm (H) X 79 cm (D)

- Shipping weight:

- 32kg

The analyser should be operated from an air-conditioned laboratory. A ¼” sampling line should be located outside the laboratory and secured to the common sampling point, ensuring that no water can enter the line.

Manual handling

- A procedure appropriate to lifting a heavy object should be used when lifting the analyzer. This procedure consists of bending at the knees while keeping your back straight and upright.

- The analyzer should be grasped at the bottom, in the front and at the rear of the unit.

- Do not attempt to lift the analyzer by the cover or other external fittings.

- While one person may lift the unit, it is desirable to have two persons lifting, one by grasping the bottom in the front and the other by grasping the bottom in the rear.

- Cables and sample tubing kept away from pathways; held overhead height if necessary.

- Walkways kept free of clutter and access to exit kept clear.

Electric safety

- Check NOx analyser casing, pump and cables are in good condition before switching on.

- Attach all cables to analyser before switching on at the mains. All equipment electrical safety tested.

Attended operation

- There is no requirement for the system to be attended during operation from a safety standpoint.

COSHH

- Ensure pump exhaust is connected to a suitable vent or charcoal scrubber to eliminate ozone.

When unpacked the instrument has the following physical specification

Footprint:

- 17.8 cm (W) X 43.2 cm (H) X 59.7 cm (D)

Weight:

- 28kg including external pump

Power:

- 220–240 VAC @ 50/60 Hz, 300 watts

Operation temperature:

- 5 min°C to 40 max°C in non-condensing environments

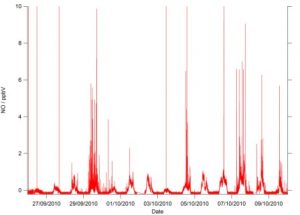

The NOx analyser provides a measurement of nitric oxide concentration in ppbV.

Field Data

- The instrument produces a range of out files and all are text format.

- The user can download (but not delete) this data from the instrument but it should be noted that this data will not have been quality controlled.

Archive data

- Data is provided in NetCDF files following the AMOF data standard

- Files contain no more than 24hr of data.

- Instrument name is

- ncas-teledyne-t200up-nox-1

- The data product(s) associated with this instrument:

- Example data file