Instrument Support Level 2

2B Technologies. Model 205

ncas-2b-2chan-o3-1

o3-concentration

£10,000

8.9 cm x 21 cm x 29.5 cm, 2.1kg

37.5 cm x 56 cm x 40 cm, 10kg

£10

Calendar

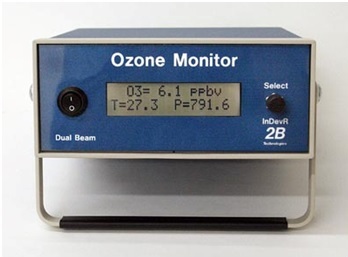

2B Technologies Ozone Monitor - Dual Channel

The dual-channel 2B Technologies Ozone monitor measures Ozone concentration using a UV photometric (254nm) technique.

The instrument has the capability to measure the amount of ozone in the air from 2 ppb concentrations up to 250 ppm. The instrument precision is 1 ppbV or 2% of the reading for a 10s average.

Due to both sample and reference flowing at the same time, the instrument has a fast response time of 2 seconds, the fastest UV-based ozone monitor available. The gas concentration is displayed in real-time and is logged via a standard RS-232 interface and data can also be logged internally. The instrument is small, lightweight and low power making it ideal for aircraft and balloon measurements where high spatial resolution is desired.

The 2-second data can be averaged to produce 10s, 1 minute, 5 minute and 1 hr data automatically.

Ozone is measured by a dual cell UV photometric gas analyser manufactured by 2B Technologies (Model 205).

Sample air is drawn continuously through an optical absorption cell where it is irradiated by monochromatic light at 253.7 nm from a stabilized low-pressure Hg discharge lamp. The absorption of this radiation by the sample air is a measure of the ambient air ozone concentration. To avoid interference from other gases absorbing light at the same wavelength and from instability in the light source, an ozone catalytic converter is used to selectively remove ozone from the sample stream either in the sample cell by using another parallel sample cell.

The Beer-Lambert equation, shown below, is used to calculate the concentration of ozone from the ratio of the two light intensities measured:

I/I0=e-acd

Where,

I0 is the light intensity measured with no ozone in the gas sample

I is the light intensity measured with ozone in the gas sample

a is the ozone absorption coefficient at 253.7 nm (1.44 x 10-5 m2/mg)

c is the mass concentration of ozone in mg/m3

d is the optical path length in m

UV photometry is the recommended primary calibration procedure.

The instrument is run in the COZI-Lab alongside at least one other ozone instrument whenever not on deployment. Two independent ozone instruments agreeing within 3% can replace the need for frequent calibrations.

External calibrations are performed before and after each instrument, deployment using the AMF ozone calibrator (Transfer Standard – TS Model 49I-PS S/N: 0703820627) which is itself calibrated annually using the primary standard reference photometer #2 (SRP#2) from the National Physical Laboratory (NPL) (traceable through the National Institute of Standards and Technology (NIST). This allows the bias on a full range of ozone values to be evaluated.

There is also a small easily transferable ozone calibrator (2B model 606), which could travel with the ozone instrument for long deployments. This calibrator is referenced regularly against the AMF ozone calibrator (detailed above). The 2B transferable standard calibrator is always adjusted to the COZI calibrator during this referencing process.

The instrument zero should be checked every month during a long deployment using an external scrubber (activated charcoal) on the inlet (20 minutes with the last 10 minutes of data being used) and as part of the calibration procedure. Results from this are recorded but the instrument is not re-zeroed unless it is clear that there is a problem with the instrument, i.e. if the standard deviation of the zero data is large.

The standard difference between two SRPs measuring zero air should not exceed (root 2 x 0.25 ppbV) = 0.49 ppbV (1 sigma), 1 minute averaging time.

Since it is an absolute measurement technique, the accuracy of the instrument is purely determined by the random error (or precision) and there is no assumed systematic error. The routine zero data (1 minute) is used to calculate the error on the data (√2σ) and if this is > 3 ppbV for minute data then the data is flagged.

To give the precision for hourly averaged data (√2σ)/ (√60).

Instrument parameters (e.g. cell pressure and cell temperature) are logged alongside those of the concentrations and used to diagnose problems.

The ozone measurements are fully traceable to the international Global Atmospheric Watch (GAW) scale (NIST Standard reference photometer SRP#2). This means that the ozone photometer used to generate ozone for the calibrations is referenced to a photometer held at NIST.

Consumables

- If temperature fluctuations are expected, as in vertical profiling applications using balloons, the instrument should be placed in a thermally insulated box (not provided).

- If analyser is to be positioned more than 3m away from the sample inlet a larger sample line and large flow pump will be needed. The ozone analyser can subsample from this larger manifold down a maximum 3m of inlet line.

- If running in a high humidity environment a nafion drier (and dry air supply) may be necessary for the inlet line although heating tape will be supplied as standard.

Costs

- Instrument Insurance

- This system must be insured by the user for £10K and covers loss, theft or damage to the instrument: damage is that over and above general wear and tear. The system has been designed to be rugged and autonomous. Even so, the end-user must respect the fact that the system is a precision optical instrument that must be treated with great care.

- The user is responsible for the instrument from the time it leaves the AMOF to the time it is returned and signed off as in an acceptable operating condition by the IS: this will be done as soon as is possible on its return.

- Public Liability Insurance

- The AMOF is not liable for any damage or injury arising from the deployment or operation of this instrument when unattended by the IS.

- Shipping Expenses

- The user is liable for all costs arising from the shipping of the instrument both to and from a deployment.

- IS T&S

- The user is responsible for coving the travel and subsistence expenses of the IS while attending the instrument.

Shipping

- The system when packed ready for shipping consists of a single small zarges box that contains the instrument, a logging laptop and some consumables.

- Shipping dimensions:

- 37.5 cm (L) x 56 cm (D) x 40 cm (H)

- Shipping weight:

- 10 kg

Installation of instrument

- The instrument requires a 12V DC source which can be supplied via either the 110-220V AC power adaptor, a cigarette lighter adapter plugged into a 12V DC source such as found in a car or many light aircraft, or from a 12V battery.

- If the instrument is being flown, the inlet should not point directly into the wind, because the resulting pressure fluctuations will result in a noisy signal.

The instrument is sensitive to temperature and so should be situated in a position with good airflow around it. If temperature fluctuations are expected, as in vertical profiling applications using balloons, the instrument should be placed in a thermally insulated box. - The instrument should be run with extra caution at times of high humidity (>90%) and if moisture is present in the sampling lines.

- It should be accessible at least every three days for visual inspection of sample lines/filters and in case basic maintenance is required.

Inlet

- The sampling line must be less than 3m (otherwise the pump gets damaged) although it can subsample from the main manifold attached to a larger pump.

- The sampling line should be made of 1/4” Teflon (or glass), ideally with Teflon fittings. 3 metres of 1.4 inch PFA tubing will be provided.

- The sampling line should not be used for more than 1 instrument (not even for another ozone instrument).

The sample should pass through a particulate filter (1.2μm) before entering the instrument. One will be included in the kit. - A Nafion dryer can be used on the sampling line if running under high humidity conditions but this needs a dry compressed air supply. A better method is to use heating tape around the inlet line.

The exhaust should not have a line connected to it (except when introducing >1 ppm) during pre-calibration.

General

- The instrument is self-enclosed so many of the potential hazards from the instrument are reduced. Do not remove any panels unless approved by instrument scientist.

Electric safety

- All instruments must be powered down before any maintenance can be performed. For major instrumentation powered through UPS, make sure there is no overload of the system.

- All electrical devices must be checked by an electronics workshop and certified.

- Operators must have knowledge of the location of exposed electrical connections.

- Ensure instruments are earthed at all times.

When unpacked both instruments have the following physical specifications:

Footprint

- 8.9 cm (L) x 21 cm (W) x 29.5 cm (H)

Weight

- 2.1 kg

Power

- 11-14V DC

- nominally 300mA at 12 V,

- 3.6 Watt

Ozone concentration measurement in ppbV.

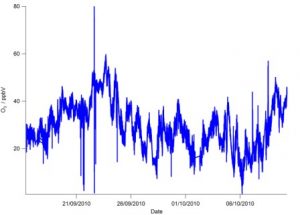

Field Data

- Data is available to download from the logging laptop as txt files.

- The user can download (but not delete) this data from the instrument but it should be noted that this data will not have been quality controlled.

Archive data

- Data is provided in NetCDF files following the AMOF data standard

- Files contain no more than 24 hours worth of data.

- Instrument name is

- ncas-2b-2chan-o3-1

- The data product(s) associated with this instrument:

- Example data file