Instrument Support Level 3

Air Quality Design Inc, High Performance, 2 Channel NOx monitor

ncas-high-sen-nox-1

nox-noxy-concentration

£100,000

95 cm x 60 cm x 175 cm. 250 kg

95 cm x 60 cm x 175 cm. 250 kg

Not Applicable

Calendar

AQD High Sensitivity and/or Fast NOx/O3

As a service to the wider community, the AMOF website “showcases” facilities that are not operated or supported by AMOF.

This is not an AMOF instrument please do not apply to AMOF for access.

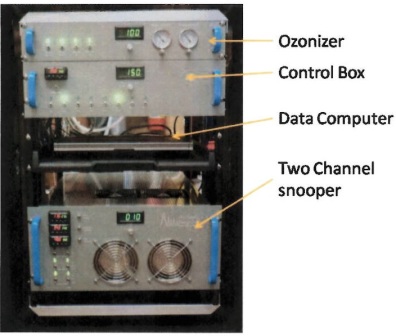

This instrument built by Air Quality Design inc. is a dual channel chemiluminescence NOx and O3 analyser. It can be configured for NOx measurements in situations where a high degree of sensitivity and a low limit of detection (<10 ppt) are required for NO and NO2 selectively. This can be coupled with high-time resolution (5 Hz) O3 on the instrument’s second channel. Alternatively, the instrument can be configured for high-time resolution (5 Hz) NO and NO2.

The instrument can run 24 hours unattended with automatic calibration carried out systematically and consistently on a daily basis. The data computer runs a custom DAQ factory interface for the instrument providing simple button-based control, graphical read-out of current signals, and graphical read-out of time series.

For NOx operation, the reagent O3 can be produced in situ using the provided O2 concentration and built-in ozoniser system. For O3 operation, the reagent NO (10 % in N2) must be provided via a gas cylinder.

The instrument is a highly sensitive chemiluminescence analyser.

It operates by detecting the photon liberated during the reaction of a nitric oxide molecule with ozone.

NO + O3 → NO2 + O2 + hv

This photon is detected by a photomultiplier tube which is cryogenically cooled to reduce the dark current in the detector and thus improve sensitivity/limit of detection and reduce noise. Depending on whether O3 or NO is supplied as the reagent gas (in large excess relative to atmospheric concentrations ~ 3-10 % by volume), the instrument is sensitive to either NO or O3. As can be seen in the reaction, the number of photons is directly proportional to the number of molecules not in excess, thus a quantitative measurement can be made. This is done under a vacuum of 2-4 torr. The vacuum also drives the sample flow through the instrument of 1.0 L/min per channel.

In order to detect NO2 it must first be converted to NO. In the AQD instrument, this is achieved with a photolytic blue light converter (BLC) which irradiates the incoming air sample at 380-410 nm in order to reduce the NO2 to NO. This NO is then detected as above.

NO2 + hv → NO + O

The conversion of this reaction is typically ~50% whereas the selectivity is ~100%. The BLC design avoids the drawbacks of older catalytic designs which reduce higher NOy species to NO also resulting in an overestimation of the true NO2 mixing ratio.

The instrument has an internal automated calibration system capable of calibrating for both NO and NO2. The calibration system also ascertains the magnitude of any signal artefact due to dark current in the detectors. The automated calibration system logs all these parameters in an output file during the calibration.

The full list of parameters is,

- Sensitivity of channel 1 in cps/ppt

- Sensitivity of channel 2 in cps/ppt

- NO2 → NO converter efficiency in %

- NO artefact in ppt

- NO2 artefact in ppt

- NO limit of detection at 1/s, 1/min & 5/min

- NO2 limit of detection at 1/s, 1/min & 5/min

- This calibration can be carried out in zero air or in ambient conditions if the background NOx concentration is not changing eg. Nighttime.

Calibration can be automated to occur periodically at a convenient time or can be on demand by the user.

The NO sensitivity is calibrated using a cylinder of 5 ppm NO in N2 (BOC, UK). A small flow (5sccm) of the calibration gas is added to the sample flow (1000sccm), allowing dilution of the calibration gas to around 25 ppb and calibration at equivalent humidity to ambient air. The calibration cylinder is itself calibrated to an NPL cylinder held in the COZI laboratory in York. NO2 is calibrated using a gas-phase titration of the NO to NO2 upon the addition of a small amount of O3.

For O3 a separate, slow-time response analyser is required to calibrate the instrument sensitivity, such as a Thermo 49i.

The instrument is essentially maintenance-free in normal operation barring changing gases. Periodic cleaning of the photolytic NO2 NO converter is required when the conversion efficiency falls below acceptable limits (~25%). The interval between cleaning will vary depending on the particulate content of the air sampled. This requires several hours of downtime – though NO data can still be recorded with only a brief interruption.

Vacuum tip seals of the vacuum pump require periodic replacement (yearly).

Consumables

- The instrument requires constant pressurised oxygen (O2) flow to operate.

- Operating a single channel requires 100ml/min or ~ 150L per day

- Operating both channels required 200ml/min or ~ 300L per day

- Zero grade compressed O2 delivered by a regulator is acceptable as is oxygen supplied by an O2 concentrator provided moisture, NOx and VOC traps are employed. Oxygen inlet pressure should be ~ 2 Bar. Gases, regulators and/or traps should be supplied by the applicant. An O2 concentrator can be provided.

- Calibration requires a flow of a Nitric Oxide (NO) standard. A nominal 5 ppm standard as usual. An NO standard can be supplied with a regulator to accompany the instrument at the agreement of both parties (~ £750). Else, the applicant should supply their own standard cylinder of known concentration and accompanying regulator. In the case that the applicant supplies their own standard, the set-up time may be extended to accommodate extra calibration steps and modification to the control software.

- For O3 measurement, constant pressurised 10 % NO in N2 is required at 35 ml / min or ~51 L / day. This cylinder and regulator should be supplied by the applicant.

- Applicants should include the cost of major pump services (£4500) for one or two pumps depending on instrument configuration (NOx only or NOx / O3)

- Additional parts that are subject to degradation during use are the diodes for the NO2 converter (replacement cost £8000) and the ozonizer units (replacement cost £3000). A typical 4-week deployment should cover replacement costs for each of these

Costs

- Instrument insurance

- This system must be insured by the user for £100K and covers loss, theft or damage to the instrument: damage is that over and above general wear and tear. The system has been designed to be rugged and autonomous. Even so, the end-user must respect the fact that the system is a precision optical instrument that must be treated with great care. The user is responsible for the instrument from the time it leaves to the time it is returned and signed off as in an acceptable operating condition by the instrument scientist. This will be done as soon as possible on its return.

- Public liability insurance

- We are not liable for any damage or injury arising from the deployment or operation of this instrument when unattended by the instrument scientist.

- Shipping expenses

- The user is liable for all costs arising from the shipping of the instrument both to and from deployment.

- IS T&S

- The user is responsible for coving the travel and subsistence expenses of the instrument scientist while attending the instrument.

Shipping

The system when packed for shipping consists of a single flight case that serves as a shock-mounted instrument rack. All 4 rubber castors have brakes. Two lifting handles per side are provided.

Shipping dimensions: 95 cm (L) x 60 cm (D) x 175 cm (H)

Shipping weight: 250 kg

Due to the size and weight (250 Kg) of the instrument, it is advised only to wheel the instrument into position; therefore, the site must have access which allows this (Ramps, elevators, forklifts etc). Carrying the instrument is not recommended.

The instrument requires ventilation due to the heat it produces so should be situated somewhere which allows unrestricted airflow. The instrument is not weatherproofed however and is fitted with a domestic 3-pin power connector so should be sited accordingly.

Manual handling

- Care when moving instrument due to high weight (250 Kg)

Compressed gases

- Precautions must be observed in the use, handling and storage of compressed gases. Refer to the site regulations for the proper procedures.

Oxidising gases

- Care must be taken in the connection and use of pure oxygen which is an accelerant.

When unpacked the instrument has the following physical specification

Footprint: 95cm (L) x 60 cm (W) x 175 cm (H)

Weight (not including shipping case): 250 kg

Power: 240V ~ 6 Amps / 1500W – single domestic outlet.

Operation temperature: -10°C to 35°C ambient

Extra floor space is required for gas cylinders etc.

The data computer sits on a tray extending 30cm in front of the instrument extending the length to 125 cm in operation.

Data is provided at 1-minute, 5-minute and 1-hour averages of 1hz data.

Field Data

- The instrument produces a range of out files and all are in text format.

- The user can download (but not delete) this data from the instrument but it should be noted that this data will not have been quality controlled.

Archive data

- Data is provided in NetCDF files following the AMOF data standard

- Files contain no more than 24hr of data.

- Instrument name is

- ncas-high-sen-nox-1

- The data product(s) associated with this instrument:

- Example data file